Sanxin Technology "PE cast film production line start-up demonstration exchange meeting" successfully concluded

- Categories:Company news

- Author:

- Origin:

- Time of issue:2017-09-25

- Views:0

(Summary description)In September of the golden autumn, fruitful results. With the sincere desire to enhance friendship, seek cooperation, and seek common development, Sanxin Technology invited some customers and suppliers to participate in the "PE cast film production line startup demonstration exchange" held by our company on September 20. meeting".

Sanxin Technology "PE cast film production line start-up demonstration exchange meeting" successfully concluded

(Summary description)In September of the golden autumn, fruitful results. With the sincere desire to enhance friendship, seek cooperation, and seek common development, Sanxin Technology invited some customers and suppliers to participate in the "PE cast film production line startup demonstration exchange" held by our company on September 20. meeting".

- Categories:Company news

- Author:

- Origin:

- Time of issue:2017-09-25

- Views:0

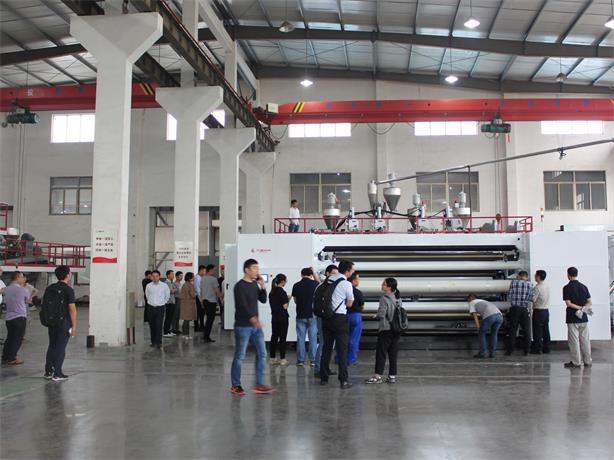

In September of the golden autumn, fruitful results. With the sincere desire to enhance friendship, seek cooperation, and seek common development, Sanxin Technology invited some customers and suppliers to participate in the "PE cast film production line startup demonstration exchange" held by our company on September 20. meeting".

In the afternoon, all the participants visited the start-up demonstration of the PE cast film production line in the production workshop. The excellent performance of the equipment won the praise of all the people present, and the smooth trial operation gave the company great confidence and encouragement. Sanxin Technology will continue to sincerely cooperate with all partners based on the concept of honesty and win-win, and continue to enhance Sanxin's brand value.

This demonstration equipment is "PE film production line", the mold width is 3600, the product thickness is 25-120 microns, and the maximum mechanical speed is 180m/min. This type of equipment is developed by Sanxin Company based on technological development and in compliance with market demand. The production of PE substrate film casting method is a major trend in the development of the times. Based on this understanding, Sanxin Company has been developing this type of equipment since 12 years. , From the initial 2000 mold width gradually increased to 2500, 2800, 3500, 3600. In the process of improving this type of equipment, we have received great help from our customers. When we encounter problems, we have provided us with valuable experience and helped us improve this type of equipment. In summary, it can be classified as the following point:

One, extrusion plasticization

Aimed at the small melting finger, high viscosity, and difficulty of plasticizing and forming of PE branch raw materials, at the same time, there is high shear heat during plasticization, and the raw materials are easy to volatilize and deposit carbon, which will cause crystal points, rigid blocks, stress lines and molds in the film production process. Flow marks affect the appearance, physical and chemical properties of the film, and affect the normal operation of the subsequent processes. We have made corresponding improvements.

1) We use multi-machine co-extrusion to balance the flow and flow rate of the materials of each layer and the extruder;

2) Change the screw structure, optimize all levels of parameters, and carry out special treatment on the surface of the screw to ensure that no residue is left when the conveying is boring;

3) The flow channel design is changed to ensure that there are no dead corners and sharp corners in the flow channel, and the flow rate of the materials everywhere is basically the same;

4) Ceramic heating is changed to electromagnetic heating, which reduces energy consumption and enhances heating uniformity.

2. Casting

In the forming part, our casting roll has been changed from the original 800 diameter to 1100 diameter, which improves the cooling and shaping efficiency. Due to the large amount of precipitates, we coordinate and communicate with the casting roll manufacturer to make the precipitates difficult to adhere to the surface of the roll through surface processing and process treatment. And in order to improve the thickness uniformity deviation of the product, and the film thickness deviation in the production process, we use automatic die head and automatic thickness measurement instead of manual methods.

Three, corona

Because the surface of the PE film is relatively sticky, the film is prone to wrinkles after corona. After many changes of the plan by Sanxin Company, this kind of unfavorable factor has been basically solved. The corona machine has been upgraded from the original 3 series to the current 4 series to solve the failure of the corona. Problem, thereby increasing the speed of the production line.

Fourth, the change of winding structure

Aiming at the phenomenon that PE film is easy to stick and fold, and is not easy to collect, we have modified the winding method to basically solve this phenomenon. And by improving the rewinding method, we have reduced the time for rewinding and minimized the loss of waste film from customers.

The above changes are the problems that Sanxin Company has discovered in the PE film production line over the years and the corresponding adjustments and improvements made, so that the equipment has been improved in the following aspects.

1) Improve the quality of plasticization and enhance the competitiveness of products;

2) Improve production efficiency, reduce waste, and reduce the cost of waste products;

3) Reduce the energy consumption of the equipment and reduce the use cost of the equipment;

4) Improve the degree of automation of products and reduce labor costs.

Scan the QR code to read on your phone

Recommended news

Browse mobile website

SANXIN

COPYRIGHT © 2021 Nantong Sanxin Plastics Equipment Technology Co.,Ltd 苏ICP备11034684号

0086-513-83214154

0086-513-83214154 david@ntsanxin.com

david@ntsanxin.com WhatsApp

WhatsApp